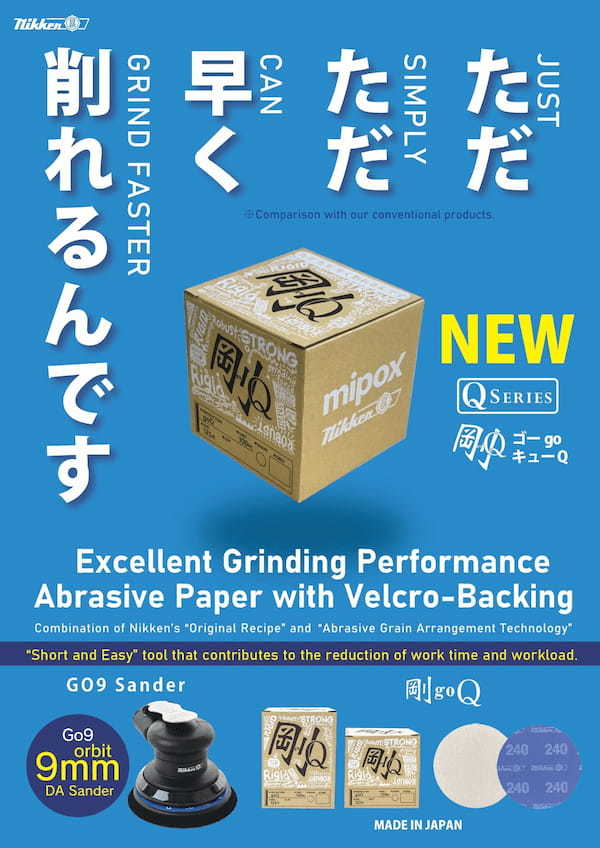

Japanese construction equipment manufacturers boast a large share of the global market. In recent years, however, the demand for construction equipment has been changing dramatically, and there is a growing need to reduce costs and improve operational efficiency, and Mipox has been receiving requests for ways to further reduce assembly time. In response to these requests, Mipox has developed two new products, the GoQ and GO9 Sanders. The new products enable the polishing work required in the assembly process of hydraulic excavators to be performed twice as fast as with conventional products (compared to our conventional products).

This article introduces the performance and advantages of the GoQ and GO9.

目次

Mipox Polishing Products

剛goQ

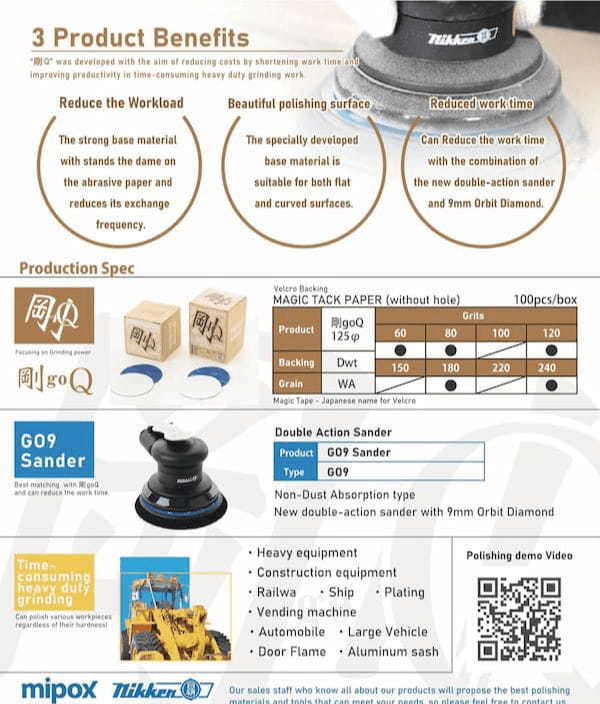

| GoQ [Specifications] | |

|---|---|

| Base material | 140g Dwt |

| Grain size: | P60/P80/P120/P180/P240 |

| Size | φ125 without hole |

| Quantity: | 100 pieces/box |

| Polished surface color | white & white (tiger pattern) |

| Color of raised fabric: | navy + white letters |

The development of GoQ began with a request from a construction equipment user who asked, "Can you suggest a polishing tool that will drastically reduce my work time?" The concept of GoQ is an "abrasive paper that focuses on grinding power" by combining Mipox's "unique manufacturing method" and "abrasive grain array." We have focused on "polishing" in the Mipox philosophy of "changing the world by painting, cutting, and polishing" and have been developing the product.

(1) Improving work efficiency: Reduction of work time / Reduction of work stress

(2) Improving environmental performance: Reduction of worker load/reduction of industrial waste.

(3) Improving quality standards: Maintaining low cost / Same quality no matter who does the work / Stable accuracy

The paper base material of rigid GoQ is thicker and stronger than Dwt (dee-weight) and conventional abrasive paper magic products. The reason for this is that according to customer feedback from construction equipment users, 60% of all abrasive paper replacements are due to damage to the base material. In the polishing process of construction machinery, burrs, narrow areas, and corners are often subject to high damage to the abrasive paper. It would be a shame to discard the abrasive paper when there is still some abrasive left on the grit surface. GoQ is an abrasive paper that can be used until the abrasive grains are completely gone.

Grain size: P60/P80/P120/P180/P240, only coarse grades are available, and size/shape is φ125 without hole only.

GO9Sander

| GO9 Sander [Specifications] | |

|---|---|

| Type | Double Action Sander |

| Specifications | One-hand type |

| Weight | 0.96Kg |

| Orbit | 9mm |

- Why did Mipox launcher an air sander?

For many years, sander manufacturers and abrasives manufacturers developed and sold sanders and abrasives separately, so there was no verification of the compatibility of sanders and abrasive papers. Therefore, Mipox has been developing air sanders based on the verification data of air sanders and abrasive papers. An air sander is a pneumatic tool used for grinding and polishing materials such as metal and resin with the force of compressed air.- What are the features of GO9 sanders?

The Orbit diameter is 9mm. Conventional Orbit diameters are available in 3mm, 5mm, 7mm, and 10mm. Customers who demanded grinding power over a large area really wanted to use 10mm, but the Orbit diameter 10mm had issues such as being "heavy" and "unbalanced and unstable." In fact, the request to make the Orbit diameter 9mm came from the voice of one of our users, a work foreman.

Advantages of Combining GoQ and GO9 Sander

1. Reduction of work stress Strong base material resists breakage and reduces frequency of replacement.

2. Beautiful polishing grain

Our unique abrasive paper base material enables polishing on both flat and curved surfaces. 3. Reduction of working time

The combination of the GoQ with high grinding performance and the new double-action sander GO9 with Orbit diameter 9mm can realize shortening work hours.Areas requiring polishing.

Arm

Why is arm polishing necessary?

Sanding for painting and scratch repair is needed.

Recommended process for arm polishing

【Abrasive Products】

Polishing of the base material: GoQ #60, #80, φ125

Putty polishing to fill weld porosities: GoQ #120 φ125 / GoQ #180 φ125

Surface polishing: GoQ #240 φ125 / GoQ #320 φ125

【Tool】

GO9 SanderHow can working time be reduced? This is a combination of the GoQ with high grinding performance and the GO9 Sander with Orbit diameter 9mm. Compared with the combination of conventional abrasive paper and Orbit 5mm, the work time can be reduced by 15%.

Cabin

Why is polishing necessary?

This is because a polishing process is needed to remove overlay, correct distortion, and scratch repair after welding of steel plates.Recommended process for cabin polishing

【Abrasive material】

Polishing of the base material: GoQ #60, #80, φ125

Putty polishing to fill weld porosities: GoQ #120 φ125 / GoQ #180 φ125

Primer surfacer sanding: GoQ #240 φ125 / GoQ #320 φ125

【Tool】

GO9 Sander

How can time be saved?

This is a combination of the GoQ with high grinding performance and the GO9 Sander with Orbit diameter 9mm. Compared with the combination of conventional abrasive paper and Orbit 5mm, the work time can be reduced by 10%.Counterweight

Why is polishing necessary?

Two types are available: the canning type in which the outside is an iron plate, and the inside is made of metal, iron ore, iron powder, etc., hardened with concrete, and the casting type. The casting type is prone to putty porosity and large distortions, which are filled with putty to hide them. Abrasive paper is used in this putty polishing.Recommended process for counterweight 【Abrasive Products】

Putty sanding: GoQ #120 φ125

Putty polishing: Rigid GoQ #180 φ125φ

Surface sanding: GoQ #240 φ125, RRAC #320 φ125

Sanding for painting: RRAC #320 φ125

【Tool】

GO9 SanderHow can time be reduced?

This is a combination of the GoQ with high grinding performance and the GO9 Sander with Orbit diameter 9mm. Compared with the combination of conventional abrasive paper and Orbit 5mm, the work time can be reduced by 30%.Environment Surrounding Hydraulic Excavators

Now that we have discussed the GoQ and GO9 sander, why is there a need to increase grinding power and reduce time using the GoQ and GO9 sander in the first place? The reason is due to changes in major markets and demand trends. The main markets are Western Europe, the U.S., and Asia, but Russia has finally arrived at the edge of growth and expansion due to increased energy demand. The expansion of the Russian market is the main reason for increased production by manufacturers that are known for their strength in cold climates. Similarly, as for the Middle East and Africa, the recent surge in resource prices and oil money are seen as the background for an increasing trend. In the U.S., North America dominates the U.S. market, which continues to be strong due to robust housing construction and road construction in the country, and some say there is a construction equipment bubble.

Among Asian countries, China is expected to see further growth in demand due to a number of large-scale projects. While Korean manufacturers have secured their share of the Chinese market for hydraulic shovels, competition is intensifying among Japanese, European, and U.S. manufacturers, who are selling high-priced, high-quality products. Also, not to be overlooked is India, which currently imposes high tariffs on finished products due to preferential treatment for domestic production, but this trend is expected to be eased.

More than 60% of construction equipment demand in Japan is shifting to the use of rental equipment. This trend is accelerating as construction companies seek to streamline their operations and reduce machinery costs. As mentioned above, we can realize an overwhelming increase in grinding power and time savings through the best combination of GoQ and GO9 Sanders. Mipox's strength lies in its ability to offer total polishing expertise that meets all customer needs, including how to use the product, rather than simply supplying the product. We will continue to provide products that bring even more value to our customers by keeping an eye on changing trends.

関連タグ - What are the features of GO9 sanders?