Polishing in Printed Circuit Board (PCB) manufacturing involves unique challenges. PCBs, made primarily of a thin plate of resin and reinforcing materials, are prone to deformation due to their delicate nature. This necessitates the use of special abrasive methods and products to achieve the desired surface quality without compromising the integrity of the PCB.

The delicacy of PCB polishing arises from the diversity of materials used in its construction, combining different hardnesses of metal and resin. This complexity is further amplified by the unevenness present in the workpiece, necessitating precision polishing to align with the undulations and remove any irregularities.

As the industry evolves, there is an increasing demand for higher density and thinner PCBs, making the polishing process more challenging. Mipox Corporation, a leader in abrasive solutions, has developed a series of products and methods to meet these evolving needs.

Innovative Abrasive Products

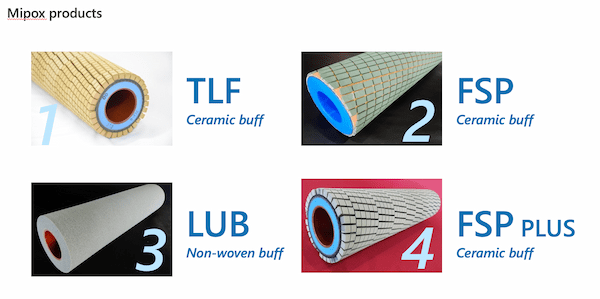

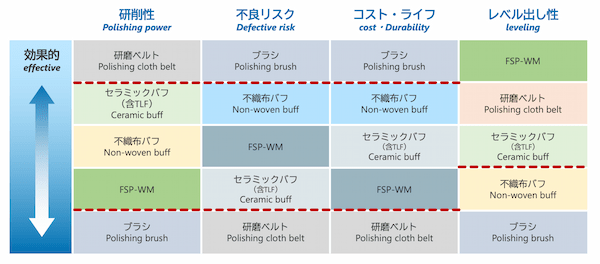

Non-Woven and Ceramic Buffs: These are essential for dealing with the undulations in PCBs. Non-woven buffs are designed for durability and cost-effectiveness, widely used for general-purpose polishing. Ceramic buffs, on the other hand, are suitable for more intensive polishing applications.

Polishing Cloth Belts and Brushes: Used for more targeted polishing applications, they effectively smooth out uneven surfaces and remove any excess material from the PCB.

Chemical Polishing and Polishing Slurries: Chemical solutions are employed for intricate polishing needs, especially where mechanical methods might be too abrasive. The use of slurries further enhances the polishing process, ensuring a uniformly smooth surface.

Revolutionary Methods

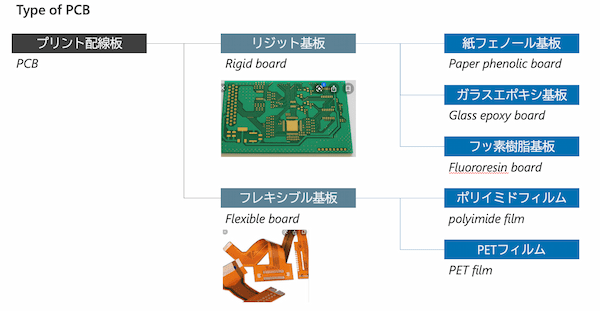

Mipox Corporation has also developed innovative methods to effectively utilize these products: Customized Polishing for Various PCB Types: Understanding the specific needs of different types of PCBs, such as rigid, flexible, and multi-layered boards, Mipox tailors its approach to each unique requirement.

Precision Polishing Techniques: To meet the precision required in PCB polishing, Mipox employs advanced techniques that align with the intricacies of the board, ensuring a defect-free and uniform finish.

Combination of Mechanical and Chemical Processes: Mipox combines mechanical polishing with chemical treatments to achieve optimal results, especially in high-density PCBs where traditional methods might be insufficient.

Focus on Durability and Cost-Efficiency: Mipox's products are designed not only for effectiveness but also with a focus on durability and cost-efficiency, making them a preferred choice in the PCB manufacturing industry.

Looking Ahead

As PCB technology continues to evolve, the demand for more sophisticated and gentle abrasive methods will increase. Mipox Corporation is at the forefront of this evolution, continually innovating and adapting its products and methods to meet the ever-changing demands of the industry.

In conclusion, the PCB polishing process is a testament to the intricate balance between precision engineering and materials science. Mipox Corporation's commitment to innovation and quality makes it a key player in the global industry, providing polishing solutions that ensure the integrity and functionality of PCBs for various applications.